Menu

- Accessories and Consumables

- Aeropress

- Chocolate shakers

- Coffee Station

- Filter coffee and tea

- Food and drinks mixers

- Hot Cold and Sparkling

- Kettles

- Knock boxes & Draws

- Lelit coffee machine accessories

- Milk Foaming Jugs

- Moka pot brewers

- Scales timers and thermometers

- Tampers mats and stands

- Wood Products

- Cafetiere

- Flasks

- Jugs - Shot Glasses and pots

- Chillout Coffee Beans

- Coffee Machines

- Display & Serving

- Water Treatment

- Hoses & Tubing

- Kitchen Equipment Parts

- Cleaning Products

- Grinders & Roasters

- Eureka Atom

- Eureka Helios

- Eureka Mignon

- Eureka Olympus

- Eureka ORO

- Eureka Zenith

- Filter Coffee Grinders

- Victoria Arduino Coffee Grinders

- Cunill Coffee Grinders

- Deli Grinders and Filter/Brew Coffee Grinders

- Domestic Coffee Grinders

- Fracino Coffee Grinders

- Hand Coffee Grinders

- Mazzer Doser Coffee Grinders

- Mazzer On Demand Coffee Grinders

- Coffee Roaster

- Machine & Grinder Parts

- Coffee machine Boiler Inspection - Rebuild - Service and Valve Service Kits

- Espresso Coffee Machine Diagnostic - Hints and Tips

- Universal Coffee machine and Grinder Parts

- Grinder Blades Listed by Manufacturer

- Silicon group seals

- Teflon coated products

- Espresso Machine Extension Feet and steam wand accessories

- Anti Vac and Boiler safety valves

- Thermostats

- Switches

- Solenoid

- Pump & Motors

- Pressure stats

- Panel Lamps

- Miscellaneous Electrical Parts

- Gas machine parts

- Flow Meters

- Contactors - Relays

- Special customer required parts.

- Vending machine parts by manufacturer

- Bianchi Vending

- Bianch Drip Trays and Panels

- Bianch Grinder Burrs and Assemblies

- Bianchi Boiler Parts

- Bianchi Brewer Components

- Bianchi Canisters, Hoppers and Tanks

- Bianchi Control Units and Touch Button Pads

- Bianchi Fittings, Pipes and Hoses

- Bianchi Flowmeter, Switches and Thermostats

- Bianchi Pumps and Motors

- Bianchi Vending Mixer System Parts

- Bunn Vending Coffee machine Parts

- Coffetek Vending Coffee Machine Parts

- Coffetek Vitro S1 Parts

- Coffetek Vitro S5 Parts

- Coffetek Vitale Parts

- Coffetek Hygiene and service kits

- Coffetek Brewer and components

- Whipper chambers

- Coffetek whipper motors, pumps and parts

- Coffetek Canisters, Chutes and spouts

- Coffetek Boiler components

- Coffetek Solenoid Valves

- Coffetek electronic components

- Coffetek Electrical Components

- Coffetek Water Supply

- Dispense Valves

- COFFETEK DRIP TRAYS, GRILLS AND FILTERS

- Coffetek Decals

- Crane Stentorfield Vending Machine parts

- Necta Vending machine parts

- Rhea Vending Coffee Machine Parts

- Bianchi Vending

- Coffee Machine Parts By Manufacturer.

- AAA Diagnostic and repair tips.

- Breville/Sage Coffee Machine Parts

- Bunn Coffee Brewer Parts

- Ascaso Coffee Machine Parts.

- ASCASO anti vacuum and safety valves

- Ascaso Boiler Elements and Gaskets

- Ascaso Boiler parts and pipework

- Ascaso Control units and Touch panels

- Ascaso Machine panels

- Ascaso Electrical parts

- Ascaso Flow meters and Solenoids

- Ascaso Group head parts

- Ascaso Pumps and pump motors

- Ascaso Steam, water valves, steam wands and water tubes

- Aurora Coffee Machine Parts

- Aurora inlet expansion valves and sight glass

- Aurora anti vacuum and safety valves

- Aurora Boiler elements

- Aurora Boiler parts and pipework

- Aurora Control units and Touch panels

- Aurora Electrical parts

- Aurora Flow meters and Solenoids

- Aurora Group head parts

- Aurora Inlet - expansion valves

- Aurora Pumps and pump motors

- Aurora Service and repair kits

- Aurora Steam, water valves, steam wands and water tubes

- Azkoyen Coffee Machine Parts

- Azkoyen Anti vacuum and safety valves

- Azkoyen Boiler Elements

- Azkoyen Boiler parts and pipework

- Azkoyen Control units and Touch panels

- Azkoyen Machine panels

- Azkoyen Electrical parts

- Azkoyen Flow meters and Solenoids

- Azkoyen Group head parts

- Azkoyen Inlet - expansion valves/one way non return valves and sight glasses

- Azkoyen Pumps and pump motors

- Azkoyen Service and repair kits

- Azkoyen Steam, water valves, steam wands and water tubes

- Bezzera Coffee Machine Parts

- Bezzera Anti Vac and Safety valves

- Bezzera Boiler Elements

- Bezzera Boiler parts and pipework

- Bezzera Control units and Touch panels

- Bezzera Machine panels

- Bezzera Electrical parts

- Bezzera Flow meters and Solenoids

- Bezzera Group head parts

- Bezzera Inlet - expansion valves/one way non return valves and sight glasses

- Bezzera Pumps and pump motors

- Bezzera Service and repair kits

- Bezzera Steam, water valves, steam wands and water tubes

- BFC Coffee Machine Parts

- BFC Anti vac and safety valves

- BFC Boiler elements

- BFC Boiler parts and pipework

- BFC Control units and Touch panels

- BFC Machine panels

- BFC Electrical parts

- BFC Flow meters and Solenoids

- BFC Group head parts

- BFC Inlet - expansion valves/one way non return valves and sight glasses

- BFC Pumps and pump motors

- BFC Service and repair kits

- BFC Steam, water valves, steam wands and water tubes

- Bianchi Coffee Machine Parts

- Brasilia Coffee Machine Parts

- Brasilia Anti Vacuum and Safety valves

- Brasilia Boiler elements

- Brasilia Boiler parts and pipework

- Brasilia Control units and Touch panels

- Brasilia Electrical parts

- Brasilia Flow meters and Solenoids

- Brasilia Group head parts

- Brasilia Inlet - expansion valves/one way non return valves and sight glasses

- Brasilia Pumps and pump motors

- Brasilia Service and repair kits

- Brasilia Steam, water valves, steam wands and water tubes

- Carimali Coffee Machine Parts

- Carimali Anti vacuum and safety valves

- Carimali Boiler element

- Carimali Boiler parts and pipework

- Carimali Control units and Touch panels

- Carimali Machine panels

- Carimali Electrical parts

- Carimali Flow meters and Solenoids

- Carimali Group head parts

- Carimali Inlet - expansion valves and sight glass

- Carimali Pumps and pump motors

- Carimali Service and repair kits

- Carimali Steam, water valves, steam wands and water tubes

- Casadio Coffee Machine Parts

- CMA - Astoria Coffee Machine Parts

- CMA Boiler elements and gaskets

- CMA Anti Vacuum and Safety valves

- CMA Boiler parts and pipework

- CMA Control units and Touch panels

- CMA Machine panels

- CMA Electrical parts

- CMA Flow meters and Solenoids

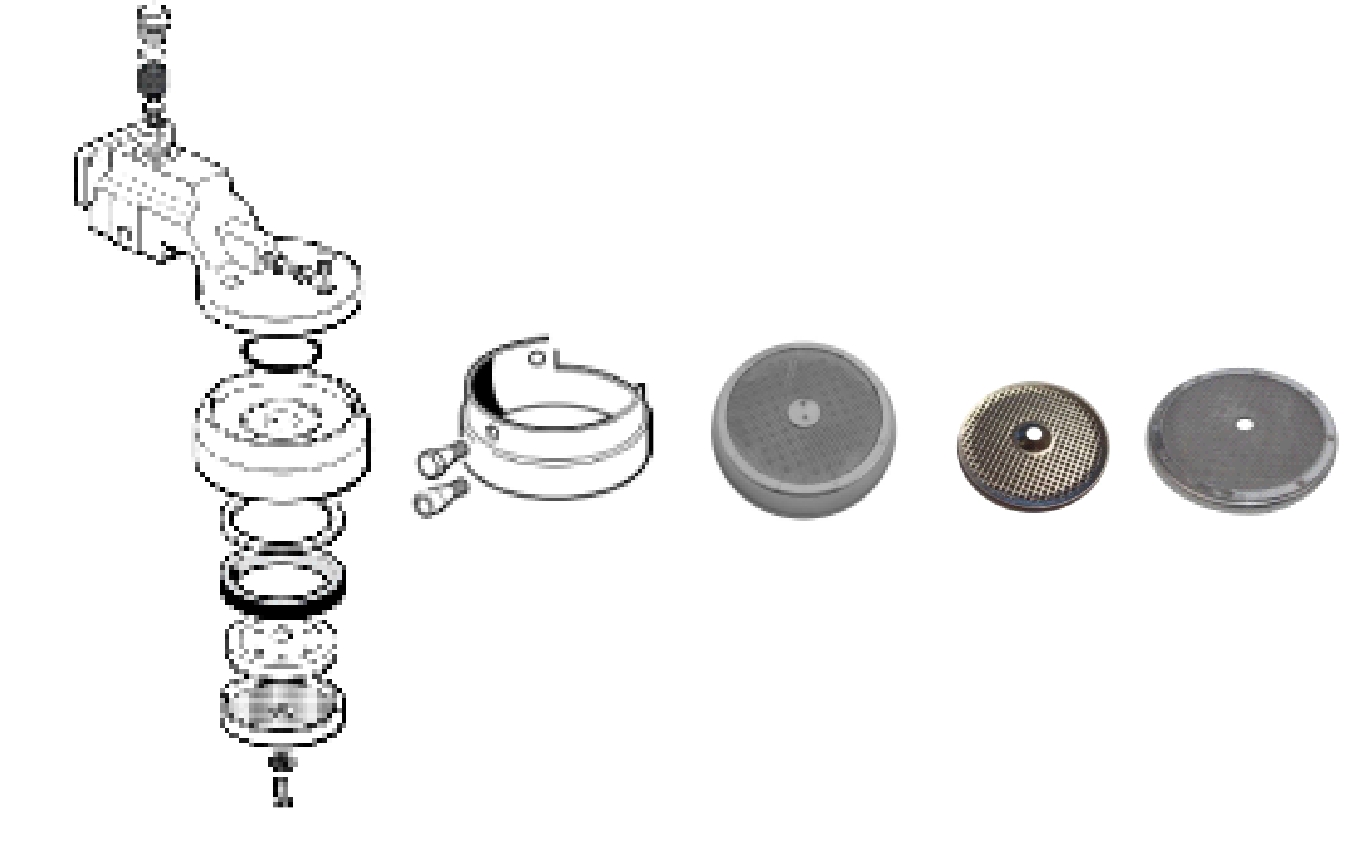

- CMA Group head parts

- CMA Inlet - expansion valves/one way non return valves and sight glasses

- CMA Pumps and pump motors

- CMA Service and repair kits

- CMA Steam, water valves, steam wands and water tubes

- Conti Coffee Machine Parts

- Conti Anti vacuum and safety valves

- Conti Boiler Elements

- Conti Boiler parts and pipework

- Conti Control units and Touch panels

- Conti Machine panels

- Conti Electrical parts

- Conti Flow meters and Solenoids

- Conti Group head parts

- Conti Inlet - expansion valves

- Conti Pumps and pump motors

- Conti Service and repair kits

- Conti Steam, water valves, steam wands and water tubes

- Dalla Corte Coffee Machines

- ECM Coffee Machine Parts

- ECM Anti vacuum valves and boiler safety valves

- ECM Boiler elements

- ECM Boiler parts and pipework

- ECM Control units and Touch panels

- ECM Machine panels

- ECM Electrical parts

- ECM Flow meters and Solenoids

- ECM Group head parts

- ECM Pumps and pump motors

- ECM Service and repair kits

- ECM Steam, water valves, steam wands and water tubes

- Elektra Coffee Machine Parts

- Elektra Anti Vacuum valves and safety valves

- Elektra boiler elements and gaskets

- Elektra Boiler parts and pipework

- Elektra Control units and Touch panels

- Elektra Machine panels

- Elektra Electrical parts

- Elektra Flow meters and Solenoids

- Elektra Group head parts

- Elektra Inlet - expansion valves/one way non return valves and sight glasses

- Elektra Pumps and pump motors

- Elektra Service and repair kits

- Elektra Steam, water valves, steam wands and water tubes

- Espressa Coffee Machine Parts

- Espressa Anti vacuum and safety valves

- Espressa Boiler parts and pipework

- Espressa Control units and Touch panels

- Espressa Electrical Parts

- Espressa Flow meters and Solenoids

- Espressa Group head parts

- Espressa Inlet - expansion valves/one way non return valves and sight glasses

- Espressa Steam and water valves - steam wands and water tubes

- Expobar Coffee machine Parts

- Expobar Anti Vacuum and Safety valves

- Expobar Boiler Elements and Gaskets

- Expobar Boiler parts and pipework

- Expobar Control units and Touch panels

- Expobar Machine panels

- Expobar Electrical parts

- Expobar Flow meters and Solenoids

- Expobar Group head parts

- Expobar Inlet - expansion valves/one way non return valves and sight glasses

- Expobar Pumps and pump motors

- Expobar Service and repair kits

- Expobar Steam, water valves, steam wands and water tubes

- Faema Coffee Machine Parts

- Faema Anti vacuum and safety valves

- Faema Boiler elements

- Faema Boiler parts and pipework

- Faema Control units and Touch panels

- Faema Machine panels

- Faema Electrical parts

- Faema Flow meters and Solenoids

- Faema Group head parts

- Faema Inlet, expansion valves/one way non return valves and sight glasses

- Faema Pumps and pump motors

- Faema Service and repair kits

- Faema Steam, water valves, steam wands and water tubes

- Fiamma Coffee Machine Parts

- Fiamma Anti vacuum and safety valves

- Fiamma Boiler Elements and gaskets

- Fiamma Boiler parts and pipework

- Fiamma Control units and Touch panels

- Fiamma Flow meters and Solenoids

- Fiamma Group head parts

- Fiamma Inlet - expansion valves/one way non return valves and sight glasses

- Fiamma Service and repair kits

- Fiamma Steam, water valves, steam wands and water tubes

- Fiorenzato Coffee Machine Parts

- Fiorenzato Anti vacuum and safety valves

- Fiorenzato Boiler elements

- Fiorenzato Boiler parts and pipework

- Fiorenzato Control units and Touch panels

- Fiorenzato Machine panels and drip trays

- Fiorenzato Electrical parts

- Fiorenzato Flow meters and Solenoids

- Fiorenzato Group head parts

- Fiorenzato Inlet - expansion valves/one way non return valves and sight glasses

- Fiorenzato Pumps and pump motors

- Fiorenzato Service and repair kits

- Fiorenzato Steam, water valves, steam wands and water tubes

- Fracino Coffee Machine Parts

- Fracino Body Panels and Feet

- Gas Machine Parts

- Fracino Anti Vac and safety valves

- Fracino boiler elements

- Fracino Boiler parts and pipework

- Fracino Control units and Touch panels

- Fracino Electrical parts

- Fracino Flow meters and Solenoids

- Fracino Group head parts

- Fracino Inlet - expansion valves and sight glasses

- Fracino Pumps and pump motors

- Fracino Service and repair kits

- Fracino Steam, water valves, steam wands and water tubes

- Futurmat/Mairali Coffee Machine Parts

- Futurmat/Mairali Anti vacuum and safety valves

- Futurmat/Mairali Boiler Elements

- Futurmat/Mairali Boiler parts and pipework

- Futurmat/Mairali Control units and Touch panels

- Futurmat/Mairali Machine panels

- Futurmat/Mairali Electrical parts

- Futurmat/Mairali Flow meters and Solenoids

- Futurmat/Mairali Group head parts

- Futurmat/Mairali Inlet - expansion valves/one way non return valves and sight glasses

- Futurmat/Mairali Pumps and pump motors

- Futurmat/Mairali Service and repair kits

- Futurmat/Mairali Steam, water valves, steam wands and water tubes

- Gaggia Coffee Machine Parts

- Gaggia Anti vacuum and safety valves

- Gaggia Boiler Elements

- Gaggia Boiler parts and pipework

- Gaggia Control units and Touch panels

- Gaggia Machine panels

- Gaggia Electrical parts

- Gaggia Flow meters and Solenoids

- Gaggia Group head parts

- Gaggia Inlet - expansion valves/one way non return valves and sight glasses

- Gaggia Pumps and pump motors

- Gaggia Service and repair kits

- Gaggia Steam, water valves, steam wands and water tubes

- Grimac Coffee Machine Parts

- Grimac Anti vacuum and safety valves

- Grimac Boiler elements and Gaskets

- Grimac Boiler parts and pipework

- Grimac Control units and Touch panels

- Grimac Machine panels

- Grimac Electrical parts

- Grimac Flow meters and Solenoids

- Grimac Group head parts

- Grimac Inlet - expansion valves/one way non return valves and sight glasses

- Grimac Pumps and pump motors

- Grimac Service and repair kits

- Grimac Steam, water valves, steam wands and water tubes

- Iberital Coffee Machine Parts

- Temperature Control and Trips

- Iberital Anti vacuum and safety valves

- Iberital Boiler elements

- Iberital Boiler parts and pipework

- Iberital Control units and Touch panels

- Iberital Machine panels

- Iberital Electrical parts

- Iberital Flow meters and Solenoids

- Iberital Group head parts

- Iberital Inlet - expansion valves/one way non return valves and sight glasses

- Iberital Pumps and pump motors

- Iberital Service and repair kits

- Iberital Steam, water valves, steam wands and water tubes

- La Cimbali Coffee Machine Parts

- Cimbali Bean to Cup Parts

- La Cimbali Anti vacuum and safety valves

- La Cimbali Boiler Elements

- La Cimbali Boiler parts and pipework

- La Cimbali Control units and Touch panels

- La Cimbali Machine panels

- La Cimbali Electrical parts

- La Cimbali Flow meters and Solenoids

- La Cimbali Group head parts

- La Cimbali Inlet - expansion valves/one way non return valves and sight glasses

- La Cimbali Pumps and pump motors

- La Cimbali Service and repair kits

- La Cimbali Steam, water valves, steam wands and water tubes

- La Rocca Coffee Machine Parts

- La Rocca Anti vacuum and safety valves

- La Rocca Boiler elements and Gaskets

- La Rocca Boiler parts and pipework

- La Rocca Control units and Touch panels

- La Rocca Flow meters and Solenoids

- La Rocca Group head parts

- La Rocca Inlet - expansion valves/one way non return valves and sight glasses

- La Rocca Steam, water valves, steam wands and water tubes

- LA Marzocco Coffee Machine Parts

- La Marzocco Anti vacuum and safety valves

- La Marzocco Boiler elements and Gaskets

- La Marzocco Boiler parts and pipework

- La Marzocco Control units and Touch panels

- La Marzocco Machine panels

- La Marzocco Electrical parts

- La Marzocco Flow meters and Solenoids

- La Marzocco Group head parts

- La Marzocco Inlet - expansion valves/one way non return valves and sight glasses

- La Marzocco Pumps and pump motors

- La Marzocco Service and repair kits

- La Marzocco Steam, water valves, steam wands and water tubes

- La Pavoni Coffee Machine Parts

- La Pavoni Anti vacuum and safety valves

- La Pavoni Boiler Elements and Gaskets

- La Pavoni Boiler parts and pipework

- La Pavoni Control units and Touch panels

- La Pavoni Machine panels

- La Pavoni Electrical parts

- La Pavoni Flow meters and Solenoids

- La Pavoni Group head parts

- La Pavoni Inlet - expansion valves/one way non return valves and sight glasses

- La Pavoni Pumps and pump motors

- La Pavoni Service and repair kits

- La Pavoni Steam, water valves, steam wands and water tubes

- La Nuvo Era Coffee Machine Parts

- Pressure Stats

- La Nuvo Era Anti vacuum and safety valves

- La Nuvo Era Boiler elements and Gaskets

- La Nuvo Era Boiler parts and pipework

- La Nuvo Era Control units and Touch panels

- La Nuvo Era Machine panels

- La Nuvo Era Electrical parts

- La Nuvo Era Flow meters and Solenoids

- La Nuvo Era Group head parts

- La Nuvo Era Inlet - expansion valves/one way non return valves and sight glasses

- La Nuvo Era Pumps and pump motors

- La Nuvo Era Steam, water valves, steam wands and water tubes

- La Scala Coffee Machine Parts

- La Scala Anti vacuum and safety valves

- La Scala Boiler elements and Gaskets

- La Scala Boiler parts and pipework

- La Scala Control units and Touch panels

- La Scala Machine panels

- La Scala Electrical parts

- La Scala Flow meters and Solenoids

- La Scala Group head parts

- La Scala Inlet - expansion valves/one way non return valves and sight glasses

- La Scala Pumps and pump motors

- La Scala Service and repair kits

- La Scala Steam, water valves, steam wands and water tubes

- Lavazza Coffee Machine Parts

- La Spaziale Coffee Machine Parts

- La Spaziale Anti Vacuum valve and Safety valves

- La Spaziale boiler elements

- La Spaziale Boiler parts and pipework

- La Spaziale Control units and Touch panels

- La Spaziale Machine panels

- La Spaziale Electrical parts

- La Spaziale Flow meters and Solenoids

- La Spaziale Group head parts

- La Spaziale Inlet - expansion valves/one way non return valves and sight glasses

- La Spaziale Pumps and pump motors

- La Spaziale Service and repair kits

- La Spaziale Steam, water valves, steam wands and water tubes

- Lelit Coffee Machine Parts

- Lelit coffee grinder parts

- Lelit Group head parts

- Lelit Pipes and fittings

- Lelit Solenoids

- Lelit Water filters

- Lelit expansion - inlet and safety valves

- Lelit machine panels and water tanks

- Lelit Steam and water valves

- Lelit water pumps and motors

- Lelit Boiler parts and pipework

- Lelit Control units and Touch panels

- Lelit Electrical Parts

- Magister Coffee Machine Parts

- Magister Anti vacuum and safety valves

- Magister Boiler elements

- Magister Boiler parts and pipework and pipework

- Magister Control units and Touch panels

- Magister Machine panels and Drip trays

- Magister Electrical parts

- Magister Flow meters and Solenoids

- Magister Group head parts

- Magister Inlet - expansion valves/one way non return valves and sight glasses

- Magister Pumps and pump motors

- Magister Service and repair kits

- Magister Steam, water valves, steam wands and water tubes

- Marcfi Coffee Machine Parts

- Marcfi Anti vacuum and safety valves

- Marcfi Boiler elements and Gaskets

- Marcfi Boiler parts and pipework

- Marcfi Control units and Touch panels

- Marcfi Electrical parts

- Marcfi Flow meters and Solenoids

- Marcfi Group head parts

- Marcfi Pumps and pump motors

- Marcfi Steam, water valves, steam wands and water tubes

- My Way Coffee Machine Parts

- My Way Anti vacuum and safety valves

- My Way Boiler parts and pipework

- My Way Control units and Touch panels

- My Way Electrical parts

- My Way Flow meters and Solenoids

- My Way Group head parts

- My Way Inlet - expansion valves/one way non return valves and sight glasses

- My Way Pumps and pump motors

- My Way Service and repair kits

- My Way Steam, water valves, steam wands and water tubes

- Reneka Coffee Machine Parts

- Reneka Anti vacuum and safety valves

- Reneka Boiler elements and Gaskets

- Reneka Boiler parts and pipework

- Reneka Control units and Touch panels

- Reneka Electrical parts

- Reneka Flow meters and Solenoids

- Reneka Group head parts

- Reneka Inlet - expansion valves/one way non return valves and sight glasses

- Reneka Pumps and pump motors

- Reneka Service and repair kits

- Reneka Steam, water valves, steam wands and water tubes

- Promac Coffee Machine Parts

- Group head parts

- Promac Anti vacuum and safety valves

- Promac Boiler elements and Gaskets

- Promac Boiler parts and Pressure Gauge

- Promac Control units and Touch panels

- Promac Machine panels

- Promac Electrical parts

- Promac Flow meters and Solenoids

- Promac Inlet - expansion valves/one way non return valves and sight glasses

- Promac Pumps and pump motors

- Promac Service and repair kits

- Promac Steam, water valves, steam wands and water tubes

- Rancilio Coffee Machine Parts

- Rancilio Anti vacuum and safety valves

- Rancilio Boiler elements and Gaskets

- Rancilio Boiler parts and pipework

- Rancilio Control units and Touch panels

- Rancilio Machine panels

- Rancilio Electrical parts

- Rancilio Flow meters and Solenoids

- Rancilio Group head parts

- Rancilio Inlet - expansion valves/one way non return valves and sight glasses

- Rancilio Pumps and pump motors

- Rancilio Service and repair kits

- Rancilio Steam, water valves, steam wands and water tubes

- Saeco Coffee Machine Parts

- Saeco Boiler elements and Gaskets

- Saeco Boiler parts and pipework

- Saeco Electrical parts

- Saeco Flow meters and Solenoids

- Saeco Group head parts

- Saeco Inlet - expansion valves/one way non return valves and sight glasses

- Saeco Pumps and pump motors

- Saeco Steam, water valves, steam wands and water tubes

- San Marco Coffee Machine Parts

- San Marco Anti vacuum and safety valves

- San Marco Boiler elements and Gaskets

- San Marco Boiler parts and pipework

- San Marco Control units and Touch panels

- San Marco Machine panels

- San Marco Electrical parts

- San Marco Flow meters and Solenoids

- San Marco Group head parts

- San Marco Inlet - expansion valves/one way non return valves and sight glasses

- San Marco Pumps and pump motors

- San Marco Service and repair kits

- San Marco Steam, water valves, steam wands and water tubes

- San Remo Coffee Machine Parts

- San Remo Body Parts

- San Remo Pressure Stats/switches

- San Remo Anti vacuum, Expansion and safety valves

- San Remo Boiler elements and Gaskets

- San Remo Boiler parts and pipework

- San Remo Control units and Touch panels

- San Remo Flow meters and Solenoids

- San Remo Group head parts

- San Remo Pumps and pump motors

- San Remo Service and repair kits

- San Remo Steam, water valves, steam wands and water tubes

- SV Italia Coffee Machine Parts

- SV Italia Anti vacuum and safety valves

- SV Italia Boiler elements and Gaskets

- SV Italia Boiler parts and pipework

- SV Italia Control units and Touch panels

- SV Italia Flow meters and Solenoids

- SV Italia Group head parts

- SV Italia Inlet - expansion valves/one way non return valves and sight glasses

- SV Italia Service and repair kits

- SV Italia Steam, water valves, steam wands and water tubes

- Simonelli Coffee Machine Parts

- Simonelli Anti vacuum and safety valves

- Simonelli Boiler elements and Gaskets

- Simonelli Boiler parts and pipework

- Simonelli Control units and Touch panels

- Simonelli Machine panels

- Simonelli Electrical parts

- Simonelli Flow meters and Solenoids

- Simonelli Group head parts

- Simonelli Inlet - expansion valves/one way non return valves and sight glasses

- Simonelli Pumps and pump motors

- Simonelli Service and repair kits

- Simonelli Steam, water valves, steam wands and water tubes

- Slayer Coffee Machine Parts

- Slayer Anti vacuum and safety valves

- Slayer Boiler elements and Gaskets

- Slayer Boiler parts and pipework

- Slayer Control units and Touch panels

- Slayer Electrical parts

- Slayer Flow meters and Solenoids

- Slayer Group head parts

- Slayer Inlet - expansion valves/one way non return valves and sight glasses

- Slayer Machine panels

- Slayer Pumps and pump motors

- Slayer Steam, water valves, steam wands and water tubes

- Synesso Coffee Machine Parts

- Synesso Anti vacuum and safety valves

- Synesso Boiler elements and Gaskets

- Synesso Boiler parts

- Synesso Control units and Touch panels

- Synesso Electrical parts

- Synesso Flow meters and Solenoids

- Synesso Group head parts

- Synesso Inlet - expansion valves/one way non return valves and sight glasses

- Synesso Machine panels

- Synesso Pumps and pump motors

- Synesso Service and repair kits

- Synesso Steam, water valves, steam wands and water tubes

- Unic Coffee Machine Parts

- Unic Anti vacuum and safety valves

- Unic Boiler elements and Gaskets

- Unic Boiler parts and pipework

- Unic Control units and Touch panels

- Unic Electrical parts

- Unic Flow meters and Solenoids

- Unic Group head parts

- Unic Inlet - expansion valves/one way non return valves and sight glasses

- Unic Pumps and pump motors

- Unic Service and repair kits

- Unic Steam, water valves, steam wands and water tubes

- VFA Coffee Machine Parts

- VFA Anti vacuum and safety valves

- VFA Boiler elements and Gaskets

- VFA Boiler parts and pipework

- VFA Control units and Touch panels

- VFA Electrical parts

- VFA Flow meters and Solenoids

- VFA Group head parts

- VFA Inlet - expansion valves/one way non return valves and sight glasses

- VFA Pumps and pump motors

- VFA Service and repair kits

- VFA Steam, water valves, steam wands and water tubes

- Vibiemme Coffee Machine Parts

- Vibiemme Anti vacuum and safety valves

- Vibiemme Boiler elements and Gaskets

- Vibiemme Boiler parts and pipework

- Vibiemme Control units and Touch panels

- Vibiemme Electrical parts

- Vibiemme Flow meters and Solenoids

- Vibiemme Group head parts

- Vibiemme Inlet - expansion valves/one way non return valves and sight glasses

- Vibiemme Pumps and pump motors

- Vibiemme Service and repair kits

- Vibiemme Steam, water valves, steam wands and water tubes

- Victoria Arduino Coffee machine Parts

- Victoria Arduino Anti vacuum and safety valves

- Victoria Arduino Boiler elements and Gaskets

- Victoria Arduino Boiler parts and pipework

- Victoria Arduino Control units and Touch panels

- Victoria Arduino Electrical parts

- Victoria Arduino Flow meters and Solenoids

- Victoria Arduino Group head parts

- Victoria Arduino Inlet - expansion valves/one way non return valves and sight glasses

- Victoria Arduino Pumps and pump motors

- Victoria Arduino Steam, water valves, steam wands and water tubes

- Visacrem Coffee Machine Parts

- Visacrem Anti vacuum and safety valves

- Visacrem Boiler elements

- Visacrem Boiler parts and pipework

- Visacrem Control units and Touch panels

- Visacrem Electrical parts

- Visacrem Flow meters and Solenoids

- Visacrem Group head parts

- Visacrem Inlet - expansion valves/one way non return valves and sight glasses

- Visacrem Pumps and pump motors

- Visacrem Service and repair kits

- Visacrem Steam, water valves, steam wands and water tubes

- Wega Coffee Machine Parts

- Wega Anti vacuum and safety valves

- Wega Boiler Elements and Gaskets

- Wega Boiler parts

- Wega Control units and Touch panels

- Wega Machine panels

- Wega Electrical parts

- Wega Flow meters and Solenoids

- Wega Group head parts

- Wega Inlet - expansion valves/one way non return valves and sight glasses

- Wega Pumps and pump motors

- Wega Service and repair kits

- Wega Steam, water valves, steam wands and water tubes

- Grinder parts by manufacturer

- Macap Coffee Grinder Parts

- Macap CPS Automatic Tamper Parts

- Burrs Listed By Manufacture

- Anfim Coffee Grinder Parts

- Aristarco Coffee Grinder Parts

- Ascaso Grinder Parts

- Azkoyen Coffee Grinder Parts

- Casadio Coffee Grinder Parts

- La Cimbali Coffee Grinder Parts

- Compak Coffee Grinder Parts

- Cunill Coffee Grinder Parts

- Eureka Coffee Grinder Parts

- Faema Coffee Grinder Parts

- Fiorenzato - Dodge Coffee Grinder Parts

- Fiorenzato Coffee Grinder Parts

- VFA Coffee Grinder Parts

- Futurmat Coffee Grinder Parts

- Gaggia Coffee Grinder Parts

- Iberital Coffee Grinder Parts

- Mahlkonig Coffee Grinder Parts

- Mazzer Coffee Grinder Parts

- Obel Coffee Grinder Parts

- Rancilio Coffee Grinder Parts

- Rossi Coffee Grinder Parts

- San Marco Coffee Grinder Parts

- San Remo Coffee Grinder Parts

- Santos Coffee Grinder parts

- Simonelli Coffee Grinder Parts

- Bravilor Coffee Machine Parts

- Bravilor Keys and Locks

- Bravilor AirPot Parts

- Bravilor Ambassador Series

- Bravilor B-HW Series

- Bravilor BFT Series

- Bravilor Bolero Series

- Bravilor Bolero XL Series

- Bravilor CB Series

- Bravilor Chiller

- Bravilor Combino Series

- Bravilor DOS Series

- Bravilor Esprecious Series

- Bravilor FreshGround Series

- Bravilor FreshMore Series

- Bravilor FreshOne Series

- Bravilor GFA Series

- Bravilor HM - HCM Series

- Bravilor HW-HWA-HWD Series

- Bravilor ISO Series

- Bravilor Matic Series

- Bravilor Mondo Series

- Bravilor Novo Series

- Bravilor Quinto Series

- Bravilor RL Series

- Bravilor Sego Series

- Bravilor TH Series

- Accessories

- BRAVILOR KMD

- Tools and repair consumables

Nav Menu 3

Nav Menu 4

Nav Menu 5

Nav Menu 6

Nav Menu 7

Nav Menu 8